Corrosion Causes Large-scale Losses In The Rust Process?

The devastating effects of corrosion are well known. Metal parts and equipment are susceptible to rust and corrosion during storage, assembly or plant shutdowns due to moisture in the air. For many years, the most common method of protecting metals from corrosion has been the use of corrosion protection coatings. While the importance of corrosion protection coatings cannot be denied, the need for other methods of controlling and preventing corrosion should not be underestimated. Corrosion does not occur in dry air. The basic problem is that the invisible water vapor present in the air will condense on any surface that is cooler than the dew point of the surrounding air. In addition, sudden changes in indoor temperature can also affect the internal humidity environment, causing condensation to appear on any surface. This subsequently leads to corrosion.

Remove a little moisture, save a lot of input

Humidity control or dehumidification is an effective method of controlling humidity in warehouses or storage areas. Controlling relative humidity not only limits the rusting of iron and steel, but also protects other humidity-sensitive materials. This article will focus on the above aspects of the corrosion phenomenon and how to prevent corrosion through humidity control.

When humidity becomes a pain point!

Aircraft, auto parts, bearings, batteries, chemicals, cartons, documents, engines, electronic components, leather goods, maps, metal parts, assemblies, gearboxes, films, food, medicines, precision watch parts, spare parts and ships all need to be stored in the raw material, semi-finished or pre-packaging stage.

The annoying enemy facing commodities during storage is "corrosion". In fact, corrosion causes staggering losses to the country every year. For any organization, the maintenance and replacement of useless parts and components caused by corrosion requires a lot of valuable resources.

"Corrosion problem" is "humidity problem"

Corrosion does not occur in dry air. The real culprit is the invisible water vapor in the air, which causes bolts to rust, damages product quality, and causes storage problems. There is always a certain amount of water vapor in the air, and this humidity is measured in relative humidity. The root of the problem is that when water vapor encounters a surface with a lower dew point temperature than the surrounding air, it condenses into water droplets. Therefore, whether it is rusty machine parts, defective plastic products, erroneous computer data, or poor quality newsprint, there is a common "culprit" behind them - humidity. This invisible killer can create chaos even in seemingly dry, air-conditioned areas.

In addition, sudden changes in indoor temperature can also disturb the internal humidity environment, causing condensation on any surface, which in turn causes corrosion.

Corrosion phenomenon

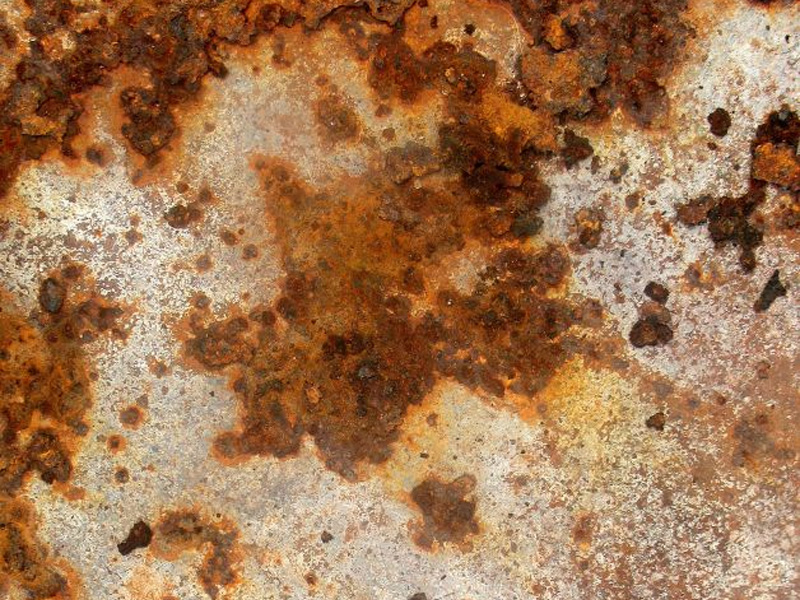

Corrosion refers to the destructive process caused by chemical or electrochemical reactions between metals or alloys and their environment. In most cases, this reaction is electrochemical in nature, that is, a current flows through a solution that can conduct an electric current in a specific area of the metal surface. This electrochemical reaction causes destructive changes in certain areas of the metal, which is the phenomenon of corrosion.

Although corrosion is the result of the combined action of many factors, the three most critical factors are:

The voltage difference between pure and impure areas

The physical conditions of temperature and humidity

The oxygen content in the air

Higher humidity can cause more water to condense on the metal surface. As the relative humidity increases, the concentration of water molecules also increases. The accumulation of the thickness of the water layer molecules eventually promotes the occurrence of ion conduction, thereby accelerating the corrosion process. For iron or steel, the reaction of ferrous ions with hydroxide ions in water will produce ferrous hydroxide, which further reacts with oxygen to produce ferric hydroxide, which is what we often call rust.

Factors that accelerate and aggravate corrosion

In absolutely pure air, even at a relative humidity of 99%, corrosion of iron hardly occurs. However, once pollutants such as sulfur dioxide or solid particles of charcoal are present, the corrosion process may start as long as the relative humidity reaches 45% or above. But in reality, it is difficult for us to encounter absolutely pure air. Whether it is clean air or polluted air, the critical humidity level is about 45%. But when the metal surface is exposed to polluted air and high relative humidity at the same time, the rate of corrosion will be significantly accelerated. Industrial pollutants, such as sulfur dioxide, will further aggravate the rate of corrosion.

Among the three key factors affecting corrosion, oxygen in the air is an unavoidable contact substance for the metal surface, and due to environmental pollution, the control of pure air and polluted air on the metal surface is also extremely limited. Although surface treatment can be used to avoid contact between water and metal surfaces, the most effective means is to control the humidity in the environment.

Therefore, we must control the relative humidity within a certain range, not only to prevent the occurrence of condensation, but also to reduce it to below the critical level where corrosion will not occur.

Organic corrosion

This form of corrosion is the most well-known and can be found in the form of mold, mildew, and fungi.

Mold, mildew, and fungi are different types of bacteria that are found in the outdoor air and are small enough to be brought indoors and attached to various surfaces. These spores remain dormant until the right temperature and humidity conditions are reached. Generally, spores will not germinate when the relative humidity is below 60%. However, the temperature conditions required for germination of different types of mold can vary greatly.

Once the conditions are ripe and the spores germinate, molds can multiply rapidly. The growth rate is mainly affected by temperature and humidity. Condensed moisture on the surface of the material provides a favorable environment for bacterial growth. In addition, the activity of microorganisms increases in high temperatures, but even at very low temperatures, microorganisms remain active to a certain extent.

The growth of microorganisms is extremely destructive to materials, causing not only the decomposition of materials, but also the reduction of mechanical properties of the product. In order to effectively prevent bacterial growth, the relative humidity needs to be controlled below 35% in most cases.