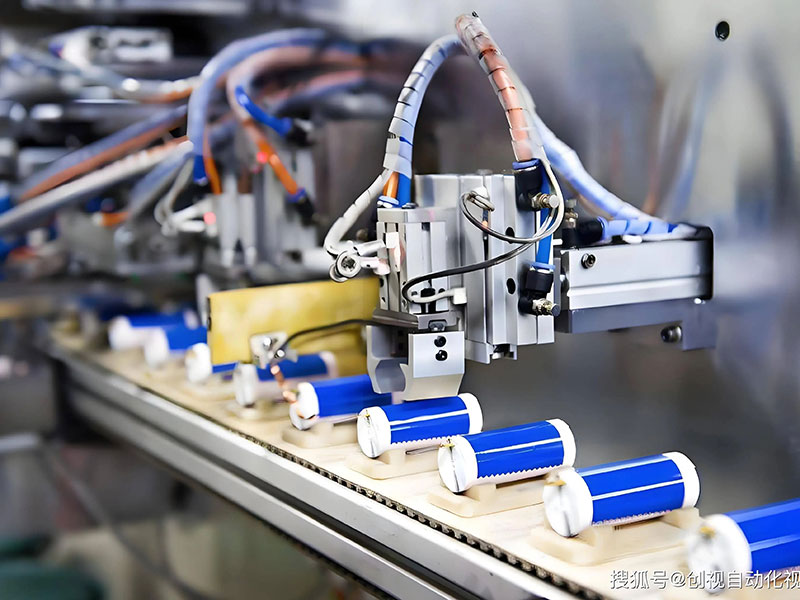

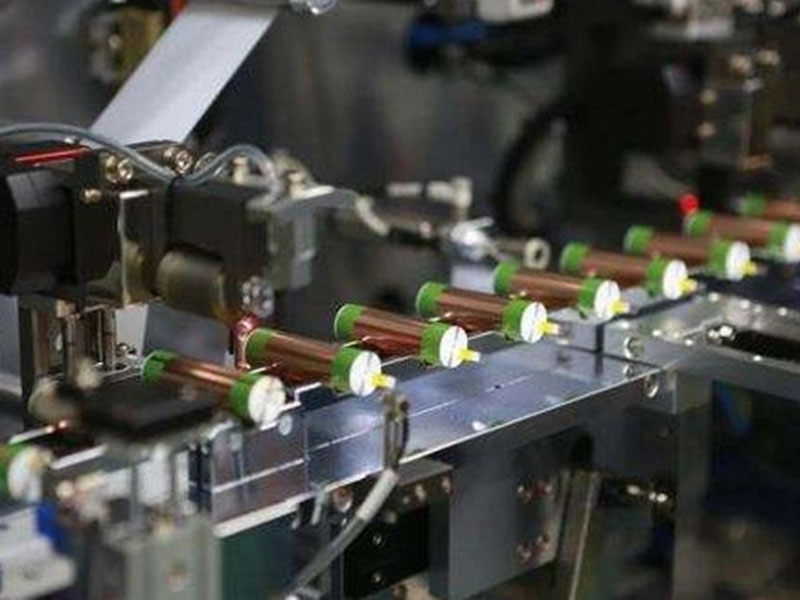

Lithium Battery Manufacturing

In lithium battery production, the use of rotary dehumidifiers is crucial for the following reasons:

- Lithium batteries contain lithium metal or lithium alloys, which are highly oxidizing to water. Moisture will react with lithium metal to produce lithium hydroxide and hydrogen, while releasing a lot of heat, which may cause fire or even explosion, which is very dangerous. Therefore, the production, processing and use of lithium batteries are particularly strict on moisture content.

- Strictly control the humidity of the production environment In the production process of lithium batteries, key processes such as sealing, injection, and coating are extremely sensitive to moisture in the air in the workshop. Once the moisture content in the air is too high, it will be absorbed by the battery, causing problems such as battery swelling and leakage, which will cause the product to be unqualified and scrapped. Therefore, controlling the humidity of the production environment is the key to ensuring battery quality.

- Advantages of rotary dehumidifiers:

- High-efficiency dehumidification performance: Rotary dehumidifiers can quickly absorb excess moisture from the production environment and release the adsorbed moisture through the built-in regeneration area, thereby continuously providing dry air to ensure that the production environment reaches the required low humidity level.

- Low dew point control: The dew point requirement of lithium battery production workshop is usually around -40℃, but in order to ensure safety, the dew point of the dehumidifier's air supply should be controlled at around -60℃.

- Significant energy-saving effect: The rotary dehumidifier adopts efficient moisture absorption rotary wheel technology, which can effectively reduce energy consumption. For example, EK's ADR-DRY X2.0 integrated high-efficiency rotary dehumidifier, through the front stage pre-cooling low-temperature direct expansion technology and waste heat type high-temperature heat pump heating regeneration air, can achieve energy saving rate of up to 45.8%.

- Strong adaptability: The rotary dehumidifier is suitable for low dew point conditions, or for treating air containing volatile organic compounds such as ethylene glycol, acetaldehyde, etc. Regeneration air up to 220℃ can be used for the rotary wheel, so the rotary wheel basically does not undergo polymerization reaction.

- Intelligent control: The rotary dehumidifier is usually equipped with an intelligent control system that can monitor and adjust the humidity in real time to ensure that the humidity of the production environment is always within the control range.

- Specific application scenarios

- Positive and negative electrode coating workshop: temperature requirement is 25℃±2, relative humidity RH≤10%-30%.

- Batching, film making, laser welding room: temperature requirement is 23±2, relative humidity ≤1% or 2%.

- Injection workshop: the requirements for the manufacturing environment are very high, usually requiring dew point Td≤-40℃ (25℃, relative humidity RH≤0.6%).