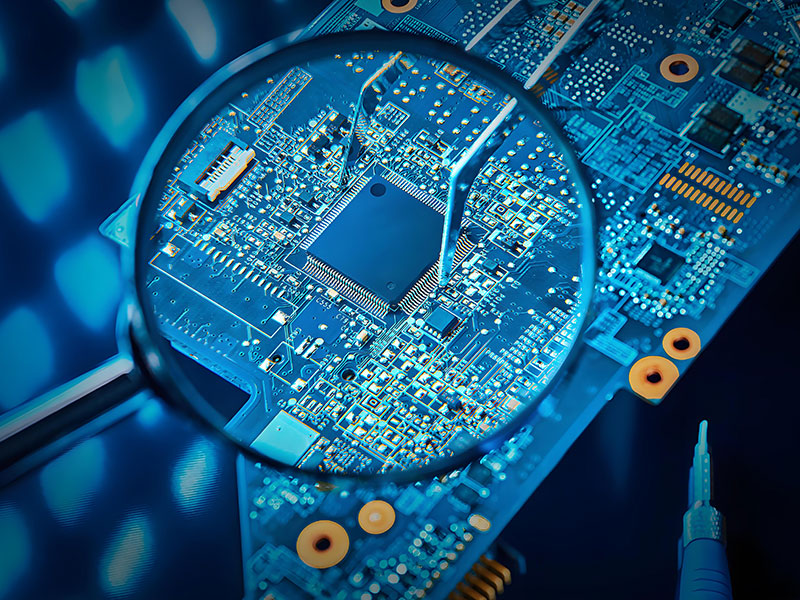

Semiconductor Industry

Used for humidity control in semiconductor manufacturing to prevent moisture from affecting precision equipment and materials.

Humidity/Process Requirements

Target Humidity Range:35~50%RH

Challenges

The semiconductor manufacturingprocess is highly sensitive to environmental conditions,and humidity plays a critical rolein ensuring the quality and reliability of components.

Condensation Risks: Excess humidity can lead to condensation on wafers,circuit boards,and precision equipment,causing defects and failures.

Corrosion: High humidity promotes corrosion in sensitive electronic components,connectors,and circuit pathways,reducing product reliability.

Static Electricity:Lowhumidity environmentscan increasethe risk of static electricity,which can damage delicate semiconductor components during production.

Contamination:Fluctuations in humidity can attract airbornecontaminants,affecting product quality in cleanroom environments.

Solutions

Rotary dehumidifiers are critical in maintaining theprecise environmentalcontrol needed for semiconductor manufacturing:

1. Condensation Prevention:

By regulating humidity levels,rotary dehumidifiers eliminate the risk ofmoisture condensation on sensitive equipment and components.

2. Corrosion Protection:

They maintain stable low-humidity conditions,preventing corrosion of electronic parts and ensuring product longevity.

3. Static Control:

Proper humidity management reduces therisk ofelectrostatic discharge,safeguarding delicate components during handling and assembly.

4. Cleanroom Compliance:

Rotarydehumidifiers help maintain strict humidity standards required in cleanroom environments, ensuring contamination-free production.

5. Energy Efficiency:

Advanced rotary dehumidifiers operate efficiently,minimizing energy consumption while maintaining optimal productionconditions.

Rotary dehumidifiers are essential for ensuring precision,reliability,and quality in semiconductor manufacturing,supportingtheproduction of advanced technologies.