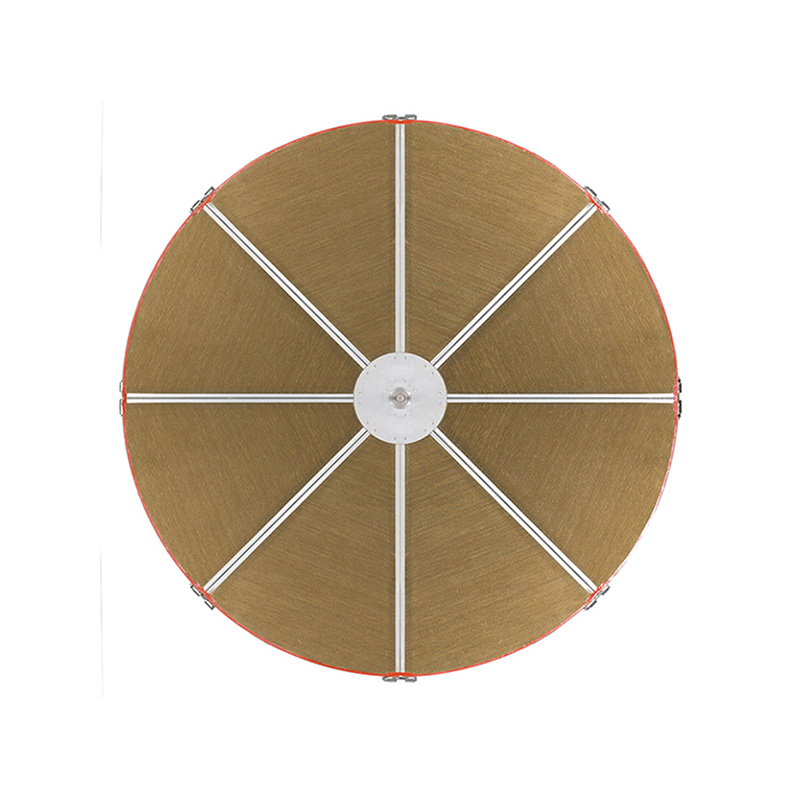

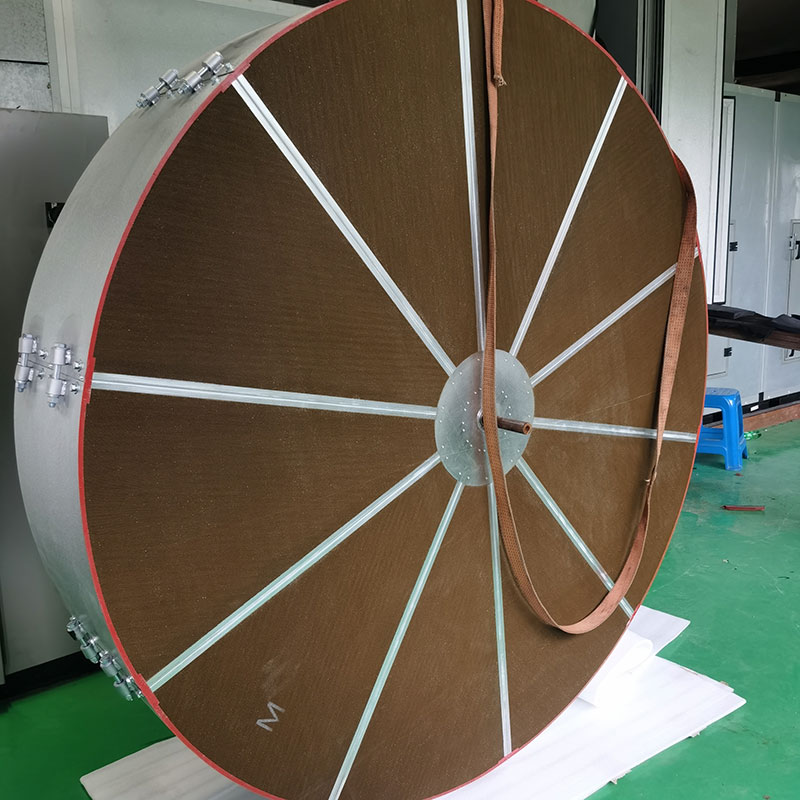

YHM Molecular Sieve Desiccant Rotor

-

37% Molecular Sieve

45% Active Silica Gel

2% Acrylic Surface Coating

Density 250Kg/M3

Detail

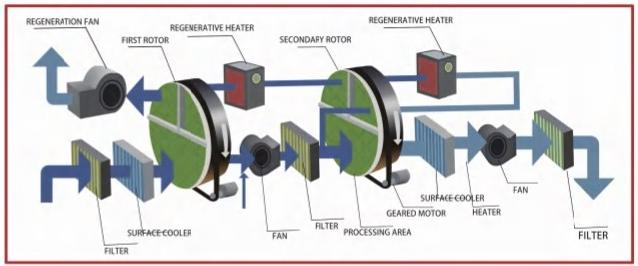

Working Principle

The Core Component Of The Rotary Dehumidifier Is The Dehumidification Rotor, Composed Offiberglass Paper And Active Silica Gel. The Two Sides Of The Rotor Are Divided Into Two Areasby Special Sealing Devices: The Processing Area And The Regeneration Area.

When Moist Air Passes Through The Processing Area Of The Rotor, The Moisture Is Absorbedby The Active Silica Gel In The Rotor, And The Treated Air Is Sent To The Space That Needs To Bedehumidified. The Slowly Rotating Rotor Carries The Saturated Moisture Into The Regeneration Area. High-Temperature Air Blown In The Opposite Direction Causes The Moisture Ab-Sorbed In The Rotor To Be Desorbed And Discharged Outside, Allowing The Rotor To Regainits Ability To Absorb Moisture And Complete The Regeneration Process.

Product Highlights

Silica Gel Wheel/Molecular Sieve Rotor

Superior Moisture Absorption Perform

Anceantibacterial And Flame Retardant

Corrosion Resistance